Last November, Sony announced a major retrenchment in its television operations and halved its yearly sales target from 40 million to 20 million sets. And Panasonic, which stands with Sony at the forefront of the industry, expects to incur a record ¥780 billion (US$10.2 billion) loss during the current fiscal year.

The decisive factor in the collapse of the Japanese television industry was a revolutionary transformation of manufacturing due to the modularisation of production and the spread of electronics manufacturing services — independent firms whose main purpose is to manufacture other companies’ products. With these developments, Japanese-style manufacturing lost its edge. Japan’s LCD panels and other major components were overwhelmed by South Korea’s bold use of capital investment to achieve economies of scale.

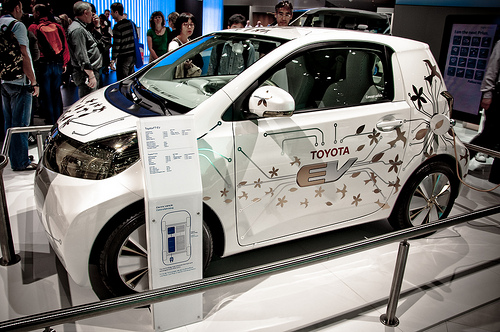

In the automotive industry too, although the paradigm change was not as harsh, the overpowering advantage of the Japanese production system has faded. Toyota was the world leader in automobile sales up to 2010, but dropped to third place in 2011. The Tohoku earthquake and tsunami dealt a brutal blow to Japan’s supply chain and greatly impacted sales. Reacting quickly, Korean cars caught up with Toyota and increased their market share by improving on quality, design and price. In addition, Toyota’s much vaunted ‘just-in-time’ production system is now a world-wide standard, and can no longer be relied on as the sole source of the Japanese automotive industry’s strength.

So, what steps are Japanese manufacturing firms taking to remain competitive in the years to come?

Japanese corporations are feverishly investing in expanded overseas operations. In 2011 they spent more than ¥5 trillion (US$65.2 billion) on mergers and acquisitions, a record high. This is in line with a common tactic of Japanese firms: taking domestic strengths abroad for horizontal development. For example, high-quality Japanese consumer goods that have been tested in the fierce domestic market are now being extensively promoted in Asia, where incomes are rising.

But the first wave of Japanese firms looking to further their reach had mixed results. Two decades ago, during the ‘bubble years’, Japanese corporations took their first commercial steps overseas. This investment boom ended in miserable failure as ‘easy’ business plans using surplus money failed in every case. The only companies that succeeded were those with production and personnel management structures as well as business models that were widely applicable beyond Japan. Toyota’s lean production system is one example. But how many companies will succeed in this second wave of overseas investment? And how will companies that already have a strong overseas presence win this next round of competition with companies from developing nations that are trying to catch up?

Komatsu, a company best known for its construction and mining vehicles, gives us a hint. It has started equipping all its vehicles with GPS systems. As a result, Komatsu and vehicle owners can now obtain an understanding of real-time operating conditions, and the former can offer customers timely information about the need for replacement purchases. The company is also building strong relationships with component manufacturers by giving them guidance in industrial technology and by offering management consulting. As the quality of the product improves, trade-in prices rise for second-hand construction vehicles and general price competitiveness is enhanced. Komatsu is thus maintaining the deep business relationship common in Japan and combining it with enhanced IT provisions.

Takahiro Fujimoto, a production management specialist at the University of Tokyo, believes that ‘strong overseas competitiveness will be possible if Japan has model production plants and a strong domestic developmental base’. As Japan uses the strong yen to advance overseas, this argument is coming to the fore. The company to watch is Toyota. It has given itself a high sales goal of 8.6 million cars in 2012. Yet it has not changed its basic policies and intends to manufacture three million cars onshore. Toyota asserts that its domestic plants will produce cutting-edge technology with strong productivity that will cancel out the higher costs. There will be a rationalisation of production controls, but, since this is Toyota, attention will also be paid to the needs of employees and the local community. To what extent Toyota can maintain this goal remains to be seen, but at this moment, with its push to emphasise process innovation, it is emblematic of Japan’s manufacturing sector.

Yoshisuke Iinuma is a contributing editor at The Oriental Economist.

This is excerpted from an article from the February issue of The Oriental Economist Report. For a copy of the full article, email the editor at [email protected].

Japan has shown that it can persevere under adversity and I think they can prosper in manufacturing despite the decline of television manufacturing. It looks as if the key lies in exporting services and products after being tested domestically.

Toyota is the leader in introducing the sustainable and green concept for car manufacturers in Japan. Toyota’s Zero Waste aim is commendable as they would like to produce energy sufficient, green cars without toxic wastes.

Japan is one of the trusted manufacturers of cars and people won’t have a second thought when they know it is made from Japan.

Dorothy Miles