The much acclaimed ‘Make in India’ campaign, launched by the Indian government, has been the key strand of the strategy for India’s economic revival. This campaign aims to establish India as a major manufacturing hub, creating millions of employment opportunities and pushing India onto a high and sustainable growth trajectory.

The Indian government is building corridors across the country to boost manufacturing and project India as a global manufacturing destination of the world. The most important of these corridors is the Delhi–Mumbai Industrial Corridor, which is one of the largest infrastructure projects planned in India, spanning six states — Uttar Pradesh, Haryana, Madhya Pradesh, Rajasthan, Gujarat and Maharashtra. It intends to boost India’s manufacturing capabilities by inviting foreign capital and technology.

The program embodies a manufacturing and export-led growth model. This model has to be understood in the context of global production systems, in which intermediate goods are shipped numerous times in multiple countries prior to being assembled together. As a result, global supply chains have become more complex and risky.

The ‘Make in India’ strategy has to place itself within the global supply chain network to contribute a greater share in world trade. Even if global production was to shift to India due to its skilled and low cost work force, availability of industry specific clusters and a reduction in non-tariff barriers, high logistics costs would negate all these advantages. Indian logistics costs are estimated to be of around 13 to 14 per cent of GDP, almost double the 7 to 8 per cent of GDP in developed countries.

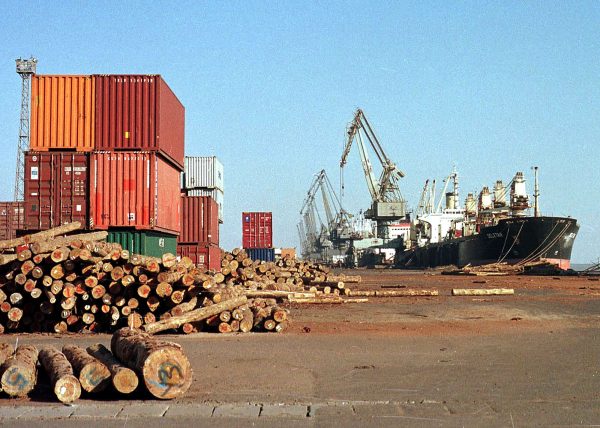

India has 12 major and 187 non-major ports. Cargo traffic, which recorded 1052 million metric tonnes in 2015, is expected to reach 1758 million metric tonnes by 2017. The Indian ports and shipping industry is vital in sustaining growth. India is the 16th largest maritime country in the world, with a coastline of about 7517 kilometres.

The government plays an important role in supporting the ports sector. It has allowed huge volumes of foreign direct investment under the automatic route for port and harbour construction and maintenance projects. It has also facilitated a 10-year tax holiday to enterprises that develop, maintain and operate ports, inland waterways and inland ports.

None of India’s major ports can routinely handle ships with large loads, so Colombo, Dubai and Singapore transship Indian containers. Indian roads are congested and railways have capacity constraints. Air cargo, which now constitutes 35 per cent of total international trade by value, faces similar problems.

Dwell time in the air cargo terminal is a critical bottleneck that compromises the competitiveness of the Indian industry. A high dwell time slows down the entire process. For the last 7–8 years, the dwell time in India has been 72 hours, far higher than the 24 hours it takes to clear 80 per cent of inbound air cargo at major international air cargo hubs like Singapore. The dwell time in Hong Kong is just 4 to 8 hours. All this points to a significant logistics deficiency in India.

Despite targeting a surge in trade share, India has never viewed its logistics competencies from a specific trade-enabling perspective.

A trade logistics network unifies elements of transportation, warehousing, trade facilitating institutions, information and communications technology and logistics service providers. When compared with the international trade logistics networks, the Indian logistics network lags on all aspects, be it infrastructure, customs or quality of services, resulting in high cost outcome, uncertainty and low reliability. Out of 160 countries, India ranks 54 in the World Bank’s 2014 Logistics Performance Index, way behind South Africa (34), Chile (42), Panama (45) and Vietnam (48).

‘Make in India’ necessitates a complete integration in the international trade logistics network so that exporters can move, store and deliver goods faster and at a lower cost to retain their competitive advantage. As India moves higher up in the value chain for specialised tasks, the regional, national and international movement of goods will increase. Fortunately, the logistics obstacles faced by India are self-imposed and are not due to any geographical disadvantages. A focused program to redesign, build and upgrade the overall logistics network from the perspective of trade is essential for the success of the ‘Make in India’ strategy.

Saurabh Bandyopadhyay is Associate Fellow at the National Council of Applied Economic Research.

I would be interested to know to what extent the author of this illuminating post sees quality control in manufacturing as a problem.

There is no case for arguing that the production of books is emblematic of manufacturing as a whole. I nevertheless offer Saurabh-ji a personal experience of mine in a spirit of helpfulness rather than disgruntlement.

In 2012, I ordered online a hard-cover copy of Prabhat’s Advanced Hindi-English dictionary, which is probably the best one- volume dictionary available.

By 2014, my copy had more or less fallen to pieces. So I ordered another copy in October of that year. This copy has in turn now fallen to pieces and become virtually unusable. I therefore use Hardev Bahri’s two-volume dictionary. Picking up one volume after another as I try to read is of course less convenient, but the binding seems better made. I suspect that these volumes will last at least another year or so before disintegrating.

By contrast, I acquired Kenkyusha’s Japanese-English dictionary in 1978, At 2110 pages, Kenkyusha is twice as long as Prabhat’s Hindi-English dictionary, but it is still in its pristine state and is perfectly usable.

I fully endorse your view that quality control in manufacturing is indeed a service-related problem. The quality of manufacturing depends on skill, R&D and complementary link to services, in which logistics play an important role.

The introductory paragraph notes that India’s manufacturing sector is much smaller than that of other countries. The author fails to note what it is in other Asian countries in a similar stage of development. he also opines that it should rise to 25 per cent. On what does he base that opinion?

The other information about the need for more logistical infrastructure, etc is quite useful. Building this would also stimulate India’s economy a great deal, right?

The basis of this prognosis linked to National Manufacturing Policy (NMP) that chalked out long term goal of achieving 25% share of GDP in manufacturing through setting up of mega industrial zones, creating 100 million jobs (by 2022) and put India at par with manufacturing prowess like China and Japan.The other assumption is correct.